CA Sort for Hanging Garments

Sort hanging inventory twice as fast as a manual sort and with no mistakes

Sort Twice as Fast

Operators can sort more than 1,500 pieces per hour on this easy-to-install, easy-to-learn system. CA Sort for Hanging Garments will communicate with your existing route accounting software to create electronic lots of uniquely identified articles. The lots can be created from a soil count or can be created based on articles recently processed in the plant.

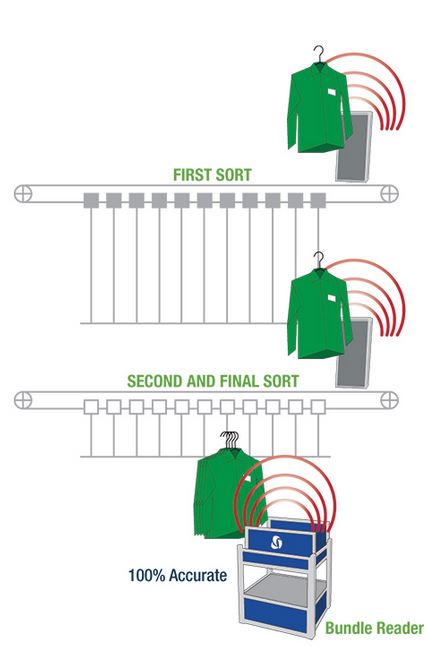

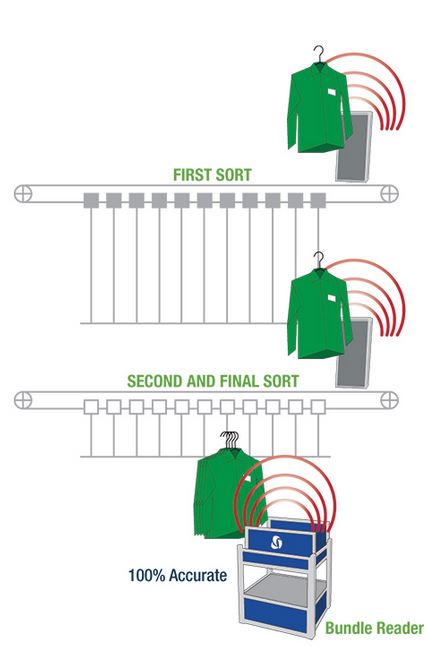

As garments are scanned at your existing conveyor, CA Sort for Hanging Garments will sort them into the appropriate lot. As each article is scanned at the sorting station, the operator is notified of the appropriate garment hook by both a screen and voice prompt. CA Sort for Hanging Garments can sort garments by size or by wearer.

Sort Twice as Fast

Operators can sort more than 1,500 pieces per hour on this easy-to-install, easy-to-learn system. CA Sort for Hanging Garments will communicate with your existing route accounting software to create electronic lots of uniquely identified articles. The lots can be created from a soil count or can be created based on articles recently processed in the plant.

As garments are scanned at your existing conveyor, CA Sort for Hanging Garments will sort them into the appropriate lot. As each article is scanned at the sorting station, the operator is notified of the appropriate garment hook by both a screen and voice prompt. CA Sort for Hanging Garments can sort garments by size or by wearer.

Data Sheet

CA Sort

CA Sort installs without major retrofitting, providing you with a low-cost solution while obtaining optimal efficiency. The easy-to-learn system means you can train new employees in minutes. Flexible and accurate sort options eliminate the need for a third sort, meaning you use less labor and complete sorting in less time. With a soil count and bundle readers, 100 percent accurate delivery can be guaranteed to your customers.